This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

MADE IN BIELLA

TECNOMECCANICABIELLESE

Specialized in planning and construction of machines and complete plants for the preparation of textile fibres for spinning since 1968...

Specialized in planning and construction of machines and complete plants for the preparation of textile fibres for spinning

Specialized in planning and construction of machines and complete plants for the preparation of textile fibres for spinning since 1968, the company gained vast experience in all sectors where staple fibres are processed (combing, woollen and semiworsted, spinning, production of non woven fabrics, felt, wadding and waste regeneration plants). Futhermore it is active in the sector of removal by suction of dust from rooms, machines, and fibres with system of automatic filtering and dust packing.

Tecnomeccanica Biellese cares the planning as well as the construction of all the components that are part of its plants. Production is characterized of an extreme flexibility and adaptability of the spaces and of the client’s needs. That’s why they always make projects on measure.

Teachings from the father Giuseppe Ploner to the two sons Luigi and Mario and to the daughter Paola that today manage the company, guarantee linearity and constancy in the planning choices and allow to maintain a well known leadership in their own sector.

Among its most famous clients, Tecnomeccanica reminds Loro Piana, Zegna, Piacenza, Botto Giuseppe, Cerruti, Reda, Barberis (all most known as hight quality and fine fabrics productors).

SECTORS

Tecnomeccanica Biellese specializes in the study, design and construction of machines for the preparation of textile fibres and of pneumatic conveying, for the following areas of textile production:

Woollen and semi-worsted spinning

- Semi-and fully automatic plants for preparing, blending, dust removal and automatic feeding of Carding-machines.

- Fully computerized management of complete production plants.

- Suction and recycling plant, for broken ends, bad-ends from condensers.

- Bailing of fibres and various conveying system.

Non-woven products

- Fibre blending plants at different stages of automation.

- Automatic card-feeding plants.

- Lines of weighing hopper feeders.

- Edge trim suction.

Dye-plants, production of synthetic fibres

- Automatic blending-bins for blending of complete lots.

- Dust suction plants for fume removal.

Spinnig-lines OPEN END

- Blending, moistening and automatic feeding plants.

- Suction and recycling of roller wastes, with air-cleaners.

For combing mills

- Automatic plants for opening, beating and blending the greasy wool with automatic feeding on to scouring line.

- Beating and dusting of scoured wool.

- Pneumatic transport to automatic storage bins for scoured wool and card feeding.

- Suction, transport and recycling of bye-products from the carding section.

- Centralised suction plant for noils and short noils in the combing department.

- Centralised filter station and air recycling.

Rag tearing mills

- Blending, moistening and dust suction of rags – automatic feeding to opening machines – re-suction and continuous conveying of waddings from tearing plant.

- Centralized dust-suction plants with automatic filtering and airrecycling.

Cloth finishing-departments

- Plants for the suction of droppings, trash and fumes, with dust filtering.

Willow wastes beating and cleaning

- Pneumatic conveying system – suction and separation of bye products-pneumatic bailing.

- Variuos Plants for the suction of trash, vapour, fumes, wood, paper, rubber, plastic, etc.

- Pneumatic and feeding of various fibre materials via conveyor belts.

- Pneumatic conveyor belt transportation of various fibres and materials.

- Metal Detector applications.

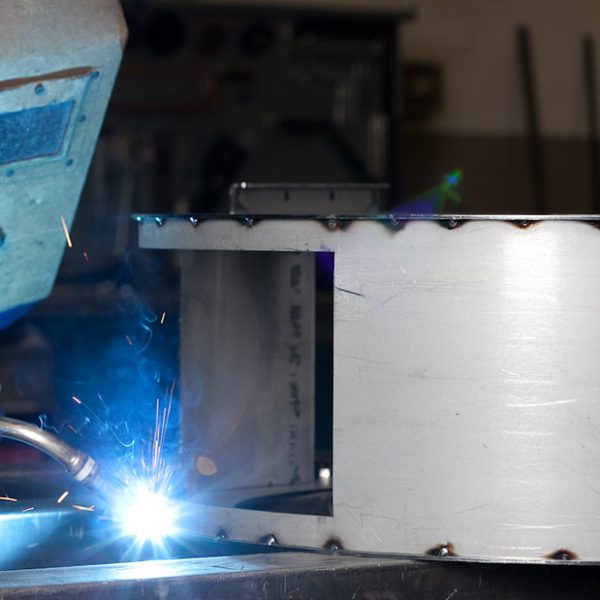

CARPENTRY

In Tecnomeccanica Biellese we have machinery and a production capacity that grant us to become third party partners starting from the project till the realization of the final good. Tecnomeccanica Biellese supplies a complete and global support co-designing the good with the customer, which is supported by experts know-how and by an expanded machinery inventory.

As it happens for our production of plants, this is a sort of “ad hoc” offer, fitted on the client, that can start from the execution of the good, but also from the feasibility analysis and the project.

We can manage and produce single units, assembled units or small-midium series in different materials.

These materials can be ferrous or not and we can also work non-vitreous composite.

Lamiera News (Maggio 2017)

( FORMATO PDF )THE GROUP

For almost half a century the group Ploner works to serve the sector of spinning wool with the companies that over time have become part of the group. The Holding , which is named as the founder of the family, Giuseppe Ploner , is now run by brothers Luigi, Paola and Mario together with the two new recruits of the third generation : Stefania and Marco .

Corporate Donors

CONTACT

Via Molino, 9 – 13891 Camburzano (BI) Italy | T. +39 015590993