Automatic Filtering system.

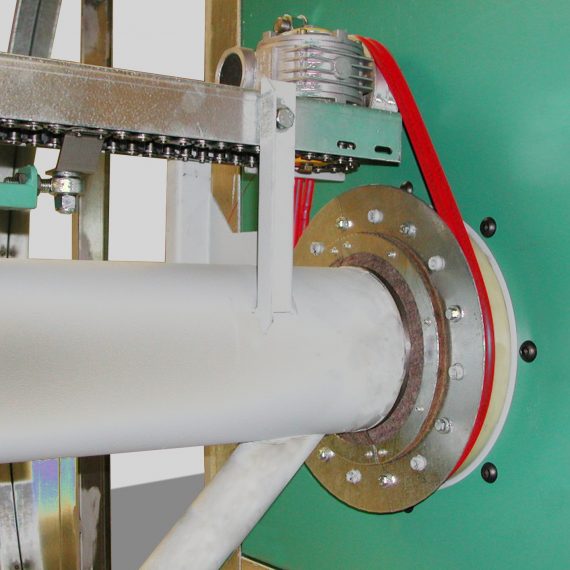

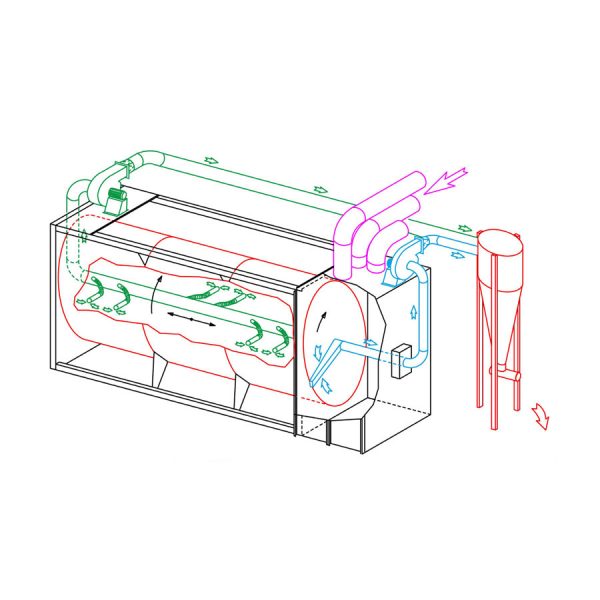

Our long experience in the field of suction of dust, waste and fabric clippings from different types of processing machines has led us to develop a new automatic filtering and cleaning system with significant advantages both from the automation and efficiency points of view. It consists of a monobloc unit optionally fitted in galvanized sheet iron panels containing a pre-filtering system for fiber separation and a drum filter to collect the particles. Because of the action of the unique automatic cleaning systems the efficiency of the unit is guaranteed. The clean air can either be recycled directly in the room or expelled externally. It is possible either to connect the unit with the air conditioning system or alternatively to have an independent system with preheating and/or humidification of the air. The separated dust particles can either be released without air pressure via a condenser-compactor located on top of containers or on bale presses. It can also be conveyed to a pneumatic bagging machine which compacts into bags “type Australia.”

- Fabric finishing departments

suction from shearing machines, raising machines and singeing machines. - Fiber blending departments for woollen and semi worsted spinning

suction from condensers, storage bins, beaters, carding willows and bale openers etc. - Rag tearing

energy saving centralized suction from tearing machines with can also be fed direct from rag feeding and packing plants. - O.E. Spinning

connection with suction lines from flat cards. Suction from hopper feeder silos, condensers for feeding flat cards and recycling of raw materials, beaters. cleaners etc. - Non-woven

suction for dust suppression on cards, fiber preparation machines, condensers etc. - Combing mills

suction of noils and carding wastes.

New special applications to other sectors with feasibility studies according to your own requirements.

The section can either be centralized, via one fan only, or subdivided into individual sections for each machine or for different lines utilizing more fans and taking into consideration the possible utilization of existing plants.