The automatic roller feeders with Silos model AS are designed to store fibers and to automatically feed Hopper Feeders, OE spinning lines or to deliver the blend on to the feed sections of different machines. There is a wide range of models available dependent on the filling height which varies from 250 to 3000 mm and in different working widths to suit individual requirements.

The model AST is equipped with a fiber opening system below the delivery rollers to provide optimum opening of the fibers which are fed into the hopper feeder. These silos are generally used in woollen spinning plants and are recommended to achieve homogenous blends.

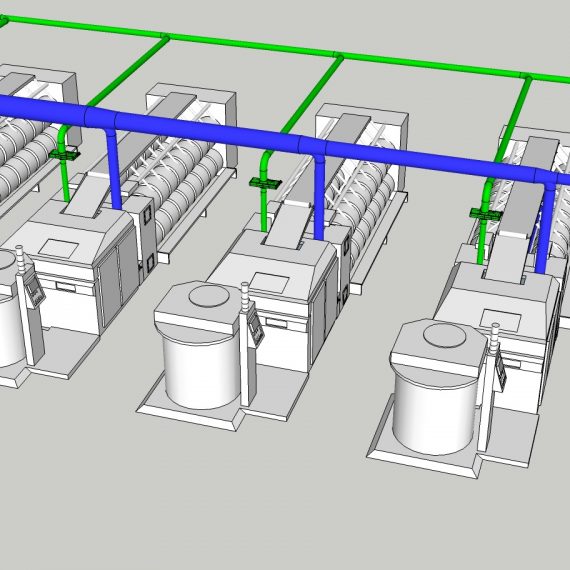

Complete suction lines for carding sets, with opening and recycling system for the hopper feeder which takes opened waste from bad/broken ends, condenser waste ends and other soft wastes from carding and spinning. The soft wastes are conveyed pneumatically into the storage silo which ensures an even and constant feed to the hopper feeder whilst maintaining a constant ratio in the hopper feeder between the blended raw material and the recycled material. Before being fed into the hopper feeder the wastes can also be conveyed into a small opener for homogeneous opening.

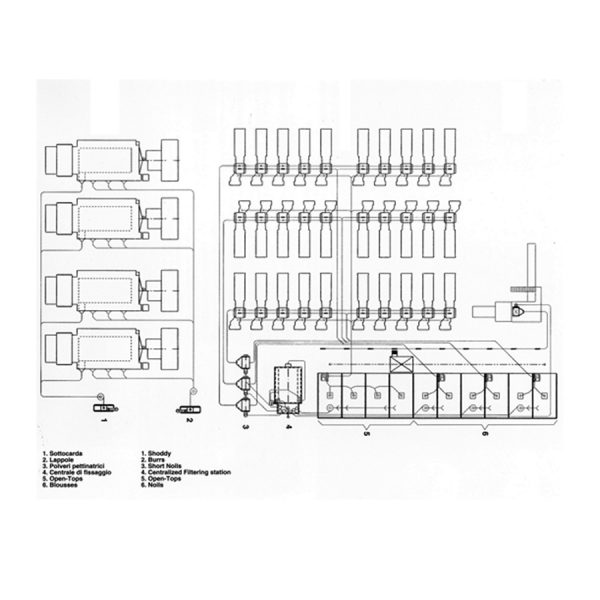

COMPLETE PLANTS FOR COMBING MILLS BYE-PRODUCTS E.G. SHODDY

with intermittent motorized scrapers positioned on the floor of the card pit and with suction of fiber either into direct baling presses or beating and continuous recycling in the same lot.

BURRS

with intermittent suction from the different points of the card and storage of the waste.

NOILS/SHORT NOILS

continuous suction from combing machines, dust removal with the possibility of going directly to the baling press.

OPEN TOPS

with continuous suction from combing machine at the exit end, storage into bins and automatic baling press. All dusty air can be conveyed to our centralized filter station.