Completely automatic card feeding process.

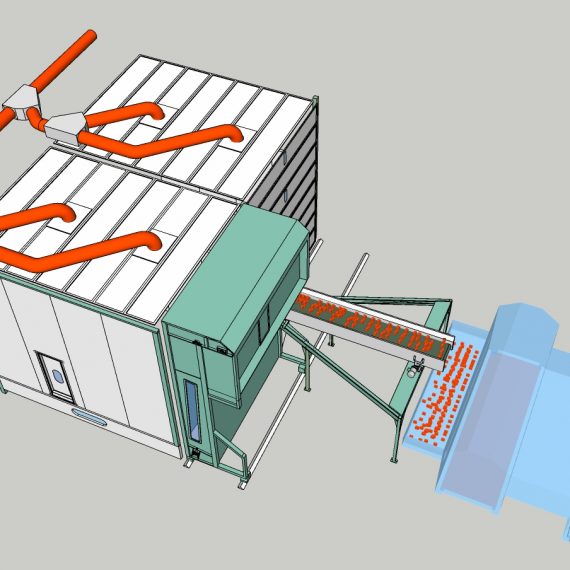

Is achieved by the use of storage bins with bin emptiers mod. SALT, working width 2500 to 4000 mm. The equipment generally consists of two storage bins of any requested size and one bin emptier, which removes the blend by cutting it across the stack from the bottom to the top.

Where possible, the bin emptier can be coupled to a feed-system, which performs the function of conveying the fibers directly into the hopper-feeder via a moving conveyor.

This operation ensures optimum fiber opening and blending, with the result of a superior final end product. The blend can be fed into the storage bins SALT via a special system of distribution in order to limit to a minimum the number of ducts needed for pneumatic conveyance, which normally involve cleaning problems for every batch of fiber material.

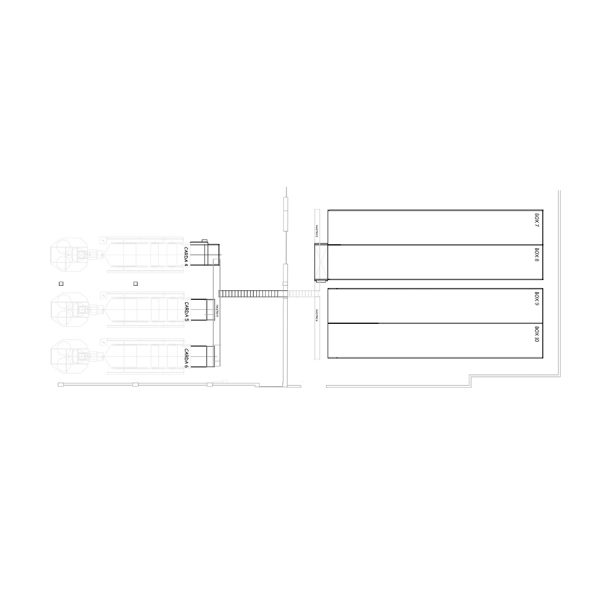

For combing mills where many cards are producing the same lot we have realized a special distribution system with a moving conveyor belt able to distribute wool to groups of 2 up to 6 cards.