This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

MADE IN BIELLA

TECNOMECCANICABIELLESE

Specialized in planning and construction of machines and complete plants for the preparation of textile fibres for spinning since 1968...

SPECIALIZED IN PLANNING AND CONSTRUCTION OF MACHINES AND COMPLETE PLANTS FOR THE PREPARATION OF TEXTILE FIBRES FOR SPINNING

AN INNOVATING SPIRIT SINCE 1969

In 1969, having gained experience over a period of 25 years in this sector, Giuseppe Ploner with his talent and entrepreneurship founded TECNOMECCANICA BIELLESE whose history is one of continual growth and expansion with constant updating in the field of the construction of fiber preparation plants.

THANK YOU BIELLA

The privilege of being Biellese is without doubt the main strong point of this company which reflects in its mentality the characteristics of this land which is known for the high quality of its own manufactured goods.

Situated on the bank of one of the generous torrents of water that is so necessary for the processing of the wool cycle and where, in the last century, dozens of textile companies were established; TECNOMECCANICA BIELLESE today includes amongst its customers the most prestigious names of “Made in Biella” textiles and also a long list of important international producer that in more recent years let new wool industry areas born all around the world. Within these names we remember Loro Piana, Zegna, Agnona, Piacenza, Botto Giuseppe, Cerruti, Barberis, Reda but also TianYu, Consinee, Erdos, Lempriere, Stucken, Incatops e Mexichem.

During its first 50 years of activity, TECNOMECCANICA BIELLESE built commercial cooperation with important groups such as Autefa Solution Italy and the French group N.Schlumberger.

These references provide a platform for the constantly evolving technological innovations which develop when working alongside the experienced technical staff of our customers who themselves renowned leaders. In this way we can satisfy the most demanding and precise requests of our various customers.

CONSTANT GROWTH

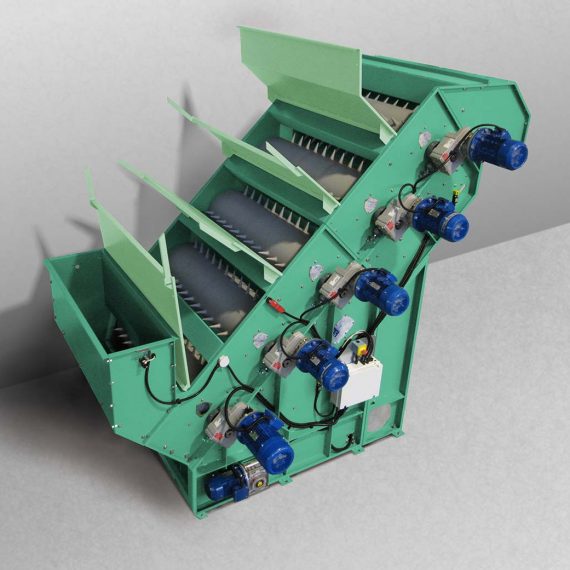

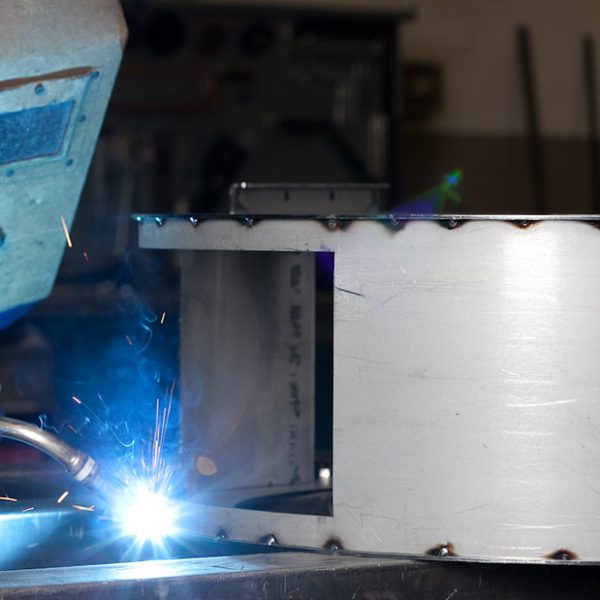

Over the last 10 years the company has continually expanded, not only has its turnover more than quadrupled, the building has been enlarged ( now covering approx. 10.000 square meters). Furthermore there has been constant investment in new technologies in both our design offices and production area.

During manufacturing all constructions are processed by number-check punching machines with simplified programs to ensure that each piece is dimensionally precise and drilled in exactly the correct positions.

Folding and cutting of metal sheets is controlled automatically which means that only assembling

and machine testing are performed manually by our skilled personnel.

PRODUCTION

The company, which specializes in the planning and construction of machines and complete plants for the preparation of textile fibers for spinning, has, over the years, gained vast experience in all sectors where staple fibers are processed like combing, spinning, production of non woven fabrics, felt, wadding, and waste regeneration plants.

Furthermore it is active in the sector of removal by suction of dust from rooms, machines, and fibers with systems of automatic filtering and dust packing.

MACHINERY PRODUCTS

SECTORS

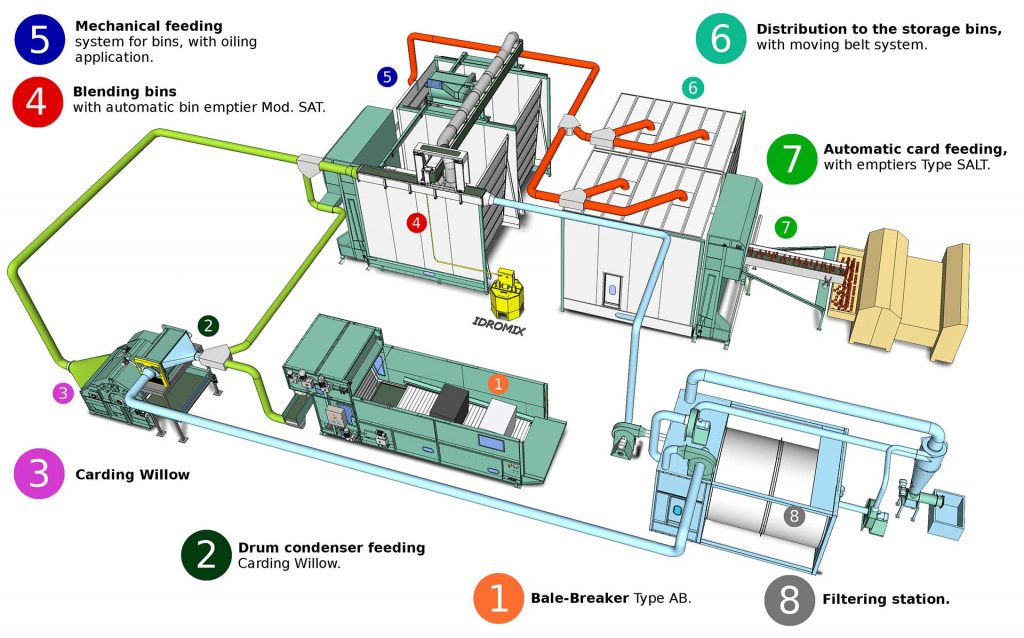

Woolen and semi-worsted spinning

We produce semi-and fully automatic plants for preparing, blending, dust removal and automatic feeding of carding-machines; fully computerized management of complete production plants; suction and recycling plant, for broken ends, bad-ends from condensers and bailing of fibers and various conveying system.

Non-woven products

We realize fiber blending plants at different stages of automation; automatic card-feeding plants; lines of weighing hopper feeders; and edge trim suction.

Dye-plants, production of synthetic fibers

We produce automatic blending-bins for blending of complete lots and dust suction plants for fume removal.

Spinning-lines O.E.

Production of blending, moistening and automatic feeding plants and suction and recycling of roller wastes, with air-cleaners.

For combing mills:

We realize automatic plants for opening, beating and blending the greasy wool with automatic feeding on to scouring line; beating and dusting of scoured wool; pneumatic transport to automatic storage bins for scoured wool and card feeding; suction, transport and recycling of bye-products from the carding section; centralized suction plant for noils and short noils in the combing department and centralized filter station and air recycling.

Rag tearing mills

Realization of blending, moistening and dust suction of rags – automatic feeding to opening machines – re-suction and continuous conveying of waddings from tearing plant and centralized dust-suction plants with automatic filtering and air recycling.

Cloth finishing-departments

We produce plants for the suction of droppings, trash and fumes, with dust filtering.

Willow wastes beating and cleaning

Production of pneumatic conveying system – suction and separation of bye products-pneumatic bailing.

VARIOUS PLANTS for the suction of trash, steam, fumes, wood, paper, rubber, plastic, etc.

PNEUMATIC conveyor belt and feeding of various fibers and materials.

PNEUMETAL DETECTOR applications.

CARPENTRY

Tecnomeccanica Biellese offers itself on the market as a third party partner a 360 degree support to its customers, from the feasibility study, to the design, up to the entire realization. The company makes itself available with a complete support, in co-design with the customer, who can benefit from the transverse know-how and the designers, as well as from a differentiated technological park for the development of their customized project. Series of single units, assembled or for small and medium series.

We clean the sea with wool

With a view to safeguarding the environment and paying attention to the reference wool textile chain, Tecnomeccanica Biellese is the leader in the creation of the Woolres project – “Wool Recycle Eco System”, an innovative 100% eco-sustainable system for cleaning up aquifers from black tides using greasy wool.

In collaboration with various departments of the Polytechnic of Turin and specific companies in the naval and chemical sector, this system was developed, which can be adapted to large and small needs, using raw wool (the one that Italian farmers have difficulty disposing of once sheared the animals because it is not fine enough to make fine yarns and fabrics) as a “selective sponge” against oily substances. Thanks to lanolin, in fact, the raw material is highly water repellent, but capable of absorbing oily liquids.

When immersed in water containing oils, it behaves exactly like a sponge, with an absorption capacity equal to 10 times its own weight, but only oily substances. Thus, proceeding repeatedly with immersion and squeezing through the automatic system designed and patented by the work team at Tecnomeccanica Biellese, the continuous cycle allows the recovery of all the surface oil that is uncontaminated by further chemical agents and therefore completely reusable, leaving flora and fauna marina completely free in their pristine environment.

A look at sustainability: plastic recycling

The sensitivity towards the environment and the propensity to new design challenges have led Tecnomeccanica Biellese to develop a new project linked to the recovery of industrial plastic by-products, including non-textile ones. This experience has led the company to re-design the machines traditionally used for fiber blending to adapt them to the dosage and mixing processes of properly shredded plastic waste products.

The use of mixing and dosing boxes to add waste recovery products to the polyester granule (PET) extrusion lines is a system that enables significant process energy savings. This technology has been developed in-house, in collaboration with manufacturers of machinery traditionally used in extrusion plants.

The use of these dosing systems also favors the recovery of unattractive wastes as the dosing precision allows to enter low percentages or in any case well determined percentages that guarantee a constant quality on the product.

THE GROUP

For almost half a century the group Ploner works to serve the sector of spinning wool with the companies that over time have become part of the group. The Holding , which is named as the founder of the family, Giuseppe Ploner , is now run by brothers Luigi, Paola and Mario together with the two new recruits of the third generation : Stefania and Marco .

CONTACT

Via Molino, 9 – 13891 Camburzano (BI) Italy | T. +39 015590993