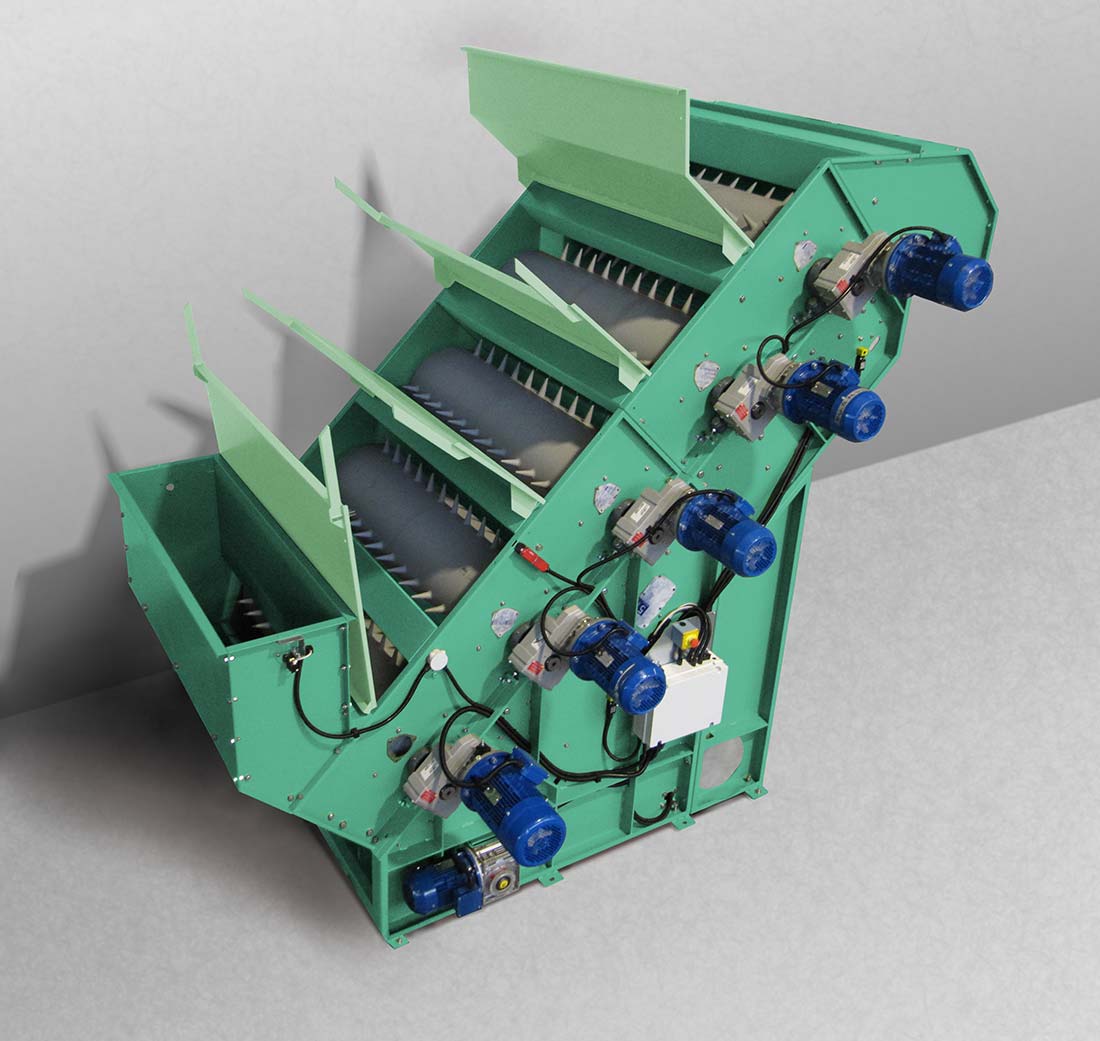

06 May CENTRALIZED FILTERING STATION

[vc_row row_type="row" use_row_as_full_screen_section="no" type="full_width" angled_section="no" text_align="left" background_image_as_pattern="without_pattern" css_animation="" z_index=""][vc_column][vc_column_text]Automatic Filtering system. Our long experience in the field of suction of dust, waste and fabric clippings from different types of processing machines has led us to develop a new automatic filtering and cleaning system with significant advantages...